Sealing Heads

For the Datz Sealing machines there are a number of

matching sealing heads, which can be used flexibly in the production process as

required:

- Sealing head VD 4 with special form for the vino-lock closure

- Top-Cap

- Stelvin-Lux closure

- Sealing heads for long caps and others

- Sealing heads with hysteresis clutch for plastic caps

- Sealing head for twist-off-caps

- Sealing head for champagne bottles

- Press-on sealing head with and without pourer

- Special heads for individual requirements

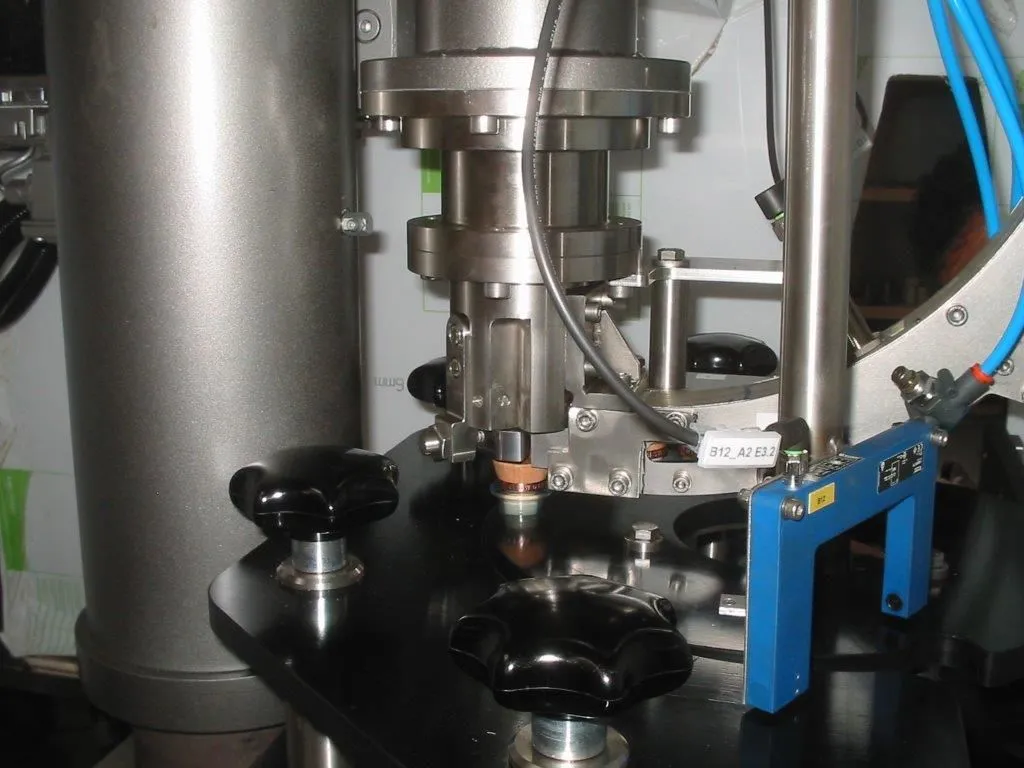

Sealing head VD 4

For the new Vino-Lock closure the Dr. Datz Company has created a special design. Only provided with flanging rolls, this sealing head offers an optional sealing operation.

Advantages of this VD 4 sealing head:

- Wear resistant materials for the flanging and edging rolls

- Integration in existing machines with the help of an adapter

- Low wear and tear because of robust constuction of all essential parts

The VD 4 sealing head is successfully used for many years in the beverage industry..

Top-Cap Sealing machine

The top-cap sealing head is distinguished as follows:

- maintenance free

- simple construction

- adjustable pressure

- exchangeable cone

- all essential parts are manufactured in stainless steel

pressure capper

Stelvin Lux Closure

The Selvin-Lux

closure is an aroma preserving aluminium roll-on closure for wine bottles.

The Selvin-Lux

closure is an aroma preserving aluminium roll-on closure for wine bottles.

First the internally plastic thread is being closed, then the metal closure without thread is being flanged.

Sealing heads for long caps and other closures

This guarantees a high flexibility and economics in the production process.

The cap is pressed from above on the sealing surface and then laterally

rolled on the thread of the wine bottle.

Sealing head with hysteresis clutch

- Sealing head with hysteresis clutch

- Exchangeable sealing elements

- Hight adjustable pick station

- Suitable for glass and PET bottles

- Used

for plastic caps

Thereby a high accuracy is achieved by the sealing process. Crooked closures are avoided.

- The torque can be adjusted on the machine .

- All parts of the sealing head are made of stainless

steel

Capacity up to 45.000 bottles per hour.

Handle cork closing unit

Quality

... is our engagement.

Many talk about quality, we live for it!

Quality is evident when it comes to the permanent practical operation of a machine.

Dr. Datz machines are very robust. Many of our machines are meanwhile more than 40 years in use. Therefore we have all kinds of spare parts on stock. .

Through this continuity within the production offer, the machines reach an extraordinary economic level.

How is this high quality achieved?

- We use seal-free material with high strength.

- Almost all materials are hardened.

- The surfaces are specialy treated .

- All parts that get in touch with water are made of stainles steel.

>>Contact us here. We are happy to help!<<